Operation and description of the multilayer fittings

Speaking of fittings, it is necessary to distinguish two main categories:

• Fittings to tighten (or to screw)

• Press fittings (or to clamp)

In addition to these, there are a series of modular manifolds that allow you to create differentiated systems that are in step with the times, suitable for various and specific applications.

• Fittings to tighten (or to screw)

• Press fittings (or to clamp)

In addition to these, there are a series of modular manifolds that allow you to create differentiated systems that are in step with the times, suitable for various and specific applications.

The design features of the multilayer fittings

The fitting houses a classic sealing ring, called O-Ring: when the pipe is connected, it passes through a metal washer and, subsequently, in this rubber ring. The fixing is in place only when the pipe is in contact with the stop at the end of the housing. At this point it is possible to tighten the nut and the connection becomes effective.

It is important, within the company context, to be able to mark the depth of the fitting on the pipe, as it can vary from model to model and depending on the manufacturer. Some companies, to do this, use customized tools and located in a special area, aimed at this purpose.

Assembly of multilayer fittings

For assembly, it is desirable to follow some rules:

1. Prepare the pipe to be connected.

2. Place bolts or inserts.

3. Mark the pipe to define the connection depth.

4. Based on the signs made, insert the tube into the fitting and check for correct placement.

5. Tighten the threaded nut between the pipe and fitting.

Once disassembled, the fittings can be mounted again by performing a series of checks on the gaskets (checking their seal) and on the signs due to the forcing between the two components.

1. Prepare the pipe to be connected.

2. Place bolts or inserts.

3. Mark the pipe to define the connection depth.

4. Based on the signs made, insert the tube into the fitting and check for correct placement.

5. Tighten the threaded nut between the pipe and fitting.

Once disassembled, the fittings can be mounted again by performing a series of checks on the gaskets (checking their seal) and on the signs due to the forcing between the two components.

Why using multilayer pipes and fittings?

The use of multilayer pipes and fittings is ideal for applications inside buildings. The conformation of the system makes it highly resistant to the pressures and temperatures of the fluids it conveys. Furthermore, it is resistant to corrosion, thermal expansion, scaling and the passage of oxygen: these problems are not negligible in this type of application.

Specifically, both for the pipe and the fittings, each layer is added to improve some features:

- Polymeric layer or rubber seal: non-toxic, acoustic attenuation, lightness, flexibility, tightness, reduced pressure drops.

- Metal layer: oxygen barrier, reduced thermal expansion, resistance to high pressures and temperatures.

Specifically, both for the pipe and the fittings, each layer is added to improve some features:

- Polymeric layer or rubber seal: non-toxic, acoustic attenuation, lightness, flexibility, tightness, reduced pressure drops.

- Metal layer: oxygen barrier, reduced thermal expansion, resistance to high pressures and temperatures.

Gnali Bocia in the multilayer fittings market

The company presents, within its catalog, a series of components for multilayer fittings with threaded junction (for example DIN2999) in the most common range of sizes on the European and Asian markets. The maximum conditions guaranteed thanks to these products are 120 ° C for the temperature and 10 bar for the pressure.

These properties are permitted by the choice of first quality materials of use:

Brass: CW617N-EN12165.

EPDM peroxide: O-Rings.

PTFE (Teflon): separating washer.

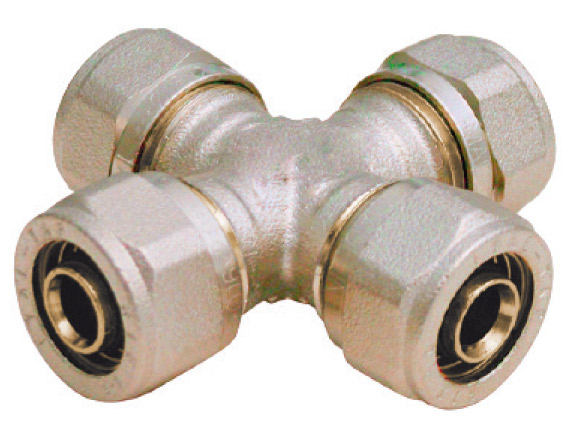

Among the most famous components are: corner fittings, T-pieces and cross fittings.

These properties are permitted by the choice of first quality materials of use:

Brass: CW617N-EN12165.

EPDM peroxide: O-Rings.

PTFE (Teflon): separating washer.

Among the most famous components are: corner fittings, T-pieces and cross fittings.

The efficiency of multilayer fittings

The multilayer fittings represent an ideal solution for structural applications inside public or private buildings. The fundamental aspects that make it possible to obtain these characteristics are:

- The choice of materials: the combination of different layers inside the multilayer pipes allows you to combine the peculiar characteristics of both, thus obtaining application advantages;

- The targeted design of the fittings allows you to minimize the discontinuity defects that may occur within a sytem, avoiding subsidence or breakage that can cause consequences even of considerable importance;

- Versatility: there are various types with different characteristic directions that make it possible to obtain very different systems, by connecting pipes in perpendicular or angled directions.

In particular, efficiency derives from the specific design of each layer and interface. In fact, using high quality materials but not properly studying the interface between one and the other layer could lead, in the long term, to significant problems for the tightness of both the fittings and the multilayer pipes.

Gnali Bocia, thanks to the experience gained in the field and thanks to the attention to the regulations, produces fittings of various types and of high quality, minimizing the risks in operation and improving the duration over time.

- The choice of materials: the combination of different layers inside the multilayer pipes allows you to combine the peculiar characteristics of both, thus obtaining application advantages;

- The targeted design of the fittings allows you to minimize the discontinuity defects that may occur within a sytem, avoiding subsidence or breakage that can cause consequences even of considerable importance;

- Versatility: there are various types with different characteristic directions that make it possible to obtain very different systems, by connecting pipes in perpendicular or angled directions.

In particular, efficiency derives from the specific design of each layer and interface. In fact, using high quality materials but not properly studying the interface between one and the other layer could lead, in the long term, to significant problems for the tightness of both the fittings and the multilayer pipes.

Gnali Bocia, thanks to the experience gained in the field and thanks to the attention to the regulations, produces fittings of various types and of high quality, minimizing the risks in operation and improving the duration over time.

The maintenance of multilayer pipe fittings

Whenever we talk about fittings, particular attention must be paid to maintenance operations. First of all, a distinction must be made between two different types of maintenance:

- Ordinary maintenance: this is maintenance that is carried out at regular intervals over time to evaluate the structure, tightness, resistance and functioning of the multilayer fittings. It is also called preventive maintenance as it allows you to prevent breakages by avoiding damage and failures that can compromise the system itself.

- Extraordinary maintenance: this is the type of maintenance that is carried out every time an inconvenience occurs that can compromise the use of the system. Compared to the previous one, it is neither predictable nor programmable.

Having highlighted this difference, it is clear that, due to their conformation, the fittings for multilayer pipes require precise and well-timed ordinary maintenance, limiting unexpected events as much as possible.

In particular, it must be verified that:

- The fitting is in perfect contact with the pipe;

- There is no damage that compromises the interface between the pipe and the fitting;

- There are no signs of corrosion on the fitting or breakage cracks resulting from operation.

- The fastening is carried out correctly, whether it's about press fittings or push fittings.

Although these are only some of the cases that can be found, it is immediate to note that even the slightest imperfection can damage the whole assembly.

- Ordinary maintenance: this is maintenance that is carried out at regular intervals over time to evaluate the structure, tightness, resistance and functioning of the multilayer fittings. It is also called preventive maintenance as it allows you to prevent breakages by avoiding damage and failures that can compromise the system itself.

- Extraordinary maintenance: this is the type of maintenance that is carried out every time an inconvenience occurs that can compromise the use of the system. Compared to the previous one, it is neither predictable nor programmable.

Having highlighted this difference, it is clear that, due to their conformation, the fittings for multilayer pipes require precise and well-timed ordinary maintenance, limiting unexpected events as much as possible.

In particular, it must be verified that:

- The fitting is in perfect contact with the pipe;

- There is no damage that compromises the interface between the pipe and the fitting;

- There are no signs of corrosion on the fitting or breakage cracks resulting from operation.

- The fastening is carried out correctly, whether it's about press fittings or push fittings.

Although these are only some of the cases that can be found, it is immediate to note that even the slightest imperfection can damage the whole assembly.

The maintenance of multilayer pipe fittings

Whenever we talk about fittings, particular attention must be paid to maintenance operations. First of all, a distinction must be made between two different types of maintenance:

Ordinary maintenance: this is maintenance that is carried out at regular intervals over time to evaluate the structure, tightness, resistance and functioning of the multilayer fittings. It is also called preventive maintenance as it allows you to prevent breakages by avoiding damage and failures that can compromise the system itself.

Extraordinary maintenance: this is the type of maintenance that is carried out every time an inconvenience occurs that can compromise the use of the system. Compared to the previous one, it is neither predictable nor programmable.

Having highlighted this difference, it is clear that, due to their conformation, the fittings for multilayer pipes require precise and well-timed ordinary maintenance, limiting unexpected events as much as possible.

In particular, it must be verified that:

- The fitting is in perfect contact with the pipe;

- There is no damage that compromises the interface between the pipe and the fitting;

- There are no signs of corrosion on the fitting or breakage cracks resulting from operation.

The fastening is carried out correctly, whether it's about press fittings or push fittings.

Although these are only some of the cases that can be found, it is immediate to note that even the slightest imperfection can damage the whole assembly.

Ordinary maintenance: this is maintenance that is carried out at regular intervals over time to evaluate the structure, tightness, resistance and functioning of the multilayer fittings. It is also called preventive maintenance as it allows you to prevent breakages by avoiding damage and failures that can compromise the system itself.

Extraordinary maintenance: this is the type of maintenance that is carried out every time an inconvenience occurs that can compromise the use of the system. Compared to the previous one, it is neither predictable nor programmable.

Having highlighted this difference, it is clear that, due to their conformation, the fittings for multilayer pipes require precise and well-timed ordinary maintenance, limiting unexpected events as much as possible.

In particular, it must be verified that:

- The fitting is in perfect contact with the pipe;

- There is no damage that compromises the interface between the pipe and the fitting;

- There are no signs of corrosion on the fitting or breakage cracks resulting from operation.

The fastening is carried out correctly, whether it's about press fittings or push fittings.

Although these are only some of the cases that can be found, it is immediate to note that even the slightest imperfection can damage the whole assembly.

28/11/2022

I contenuti di questo sito non hanno carattere di periodicità e non rappresentano 'prodotto editoriale'.